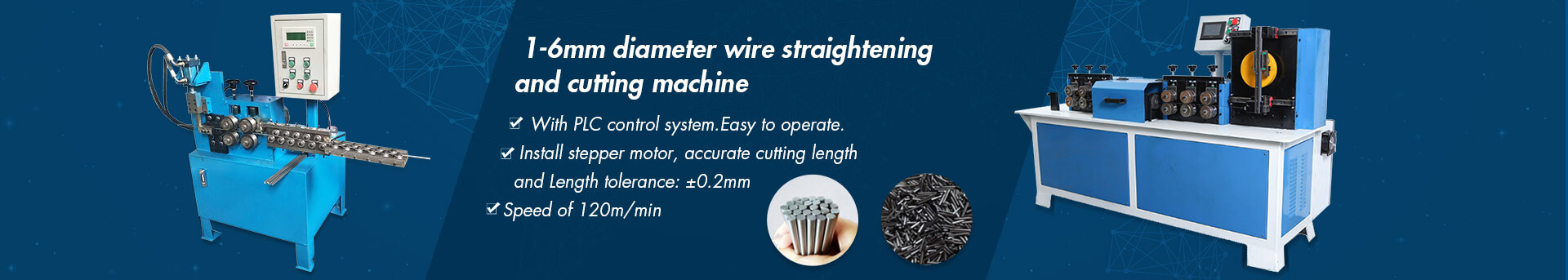

QIPANG 1-3mm straightener machine and cutting machine straightening mechanism

1, Single and dual plane straightener models JZQ 8-20/5 BV

2,Quantity of roller in stock 5 ,From 5 ~ 19 rollers

3,Roller diameters 70mm-120mm (2.8688"---4.7245")

4,Adjustable rollers on the upper row

5, Rollers available for light or heavy duty applications

6,Model AS/AD for wire R = 60 N/mm2 (8400 psi) max. with normal rollers (single or double bearing)

7,Rollers are standard "V" groove profiles but can be provided with "U" grooves 9,according to customer requirements

8,Electrical appliances: standard 0.75KW+1:30 reducer, speed 10 m/min, motor reducer can choose different power (machine speed and voltage can be customized.)

9,Power supply: 380V, three-phase electricity, 50HZ

10,All components are installed on a table

*Wire Guide included

Straightener Type

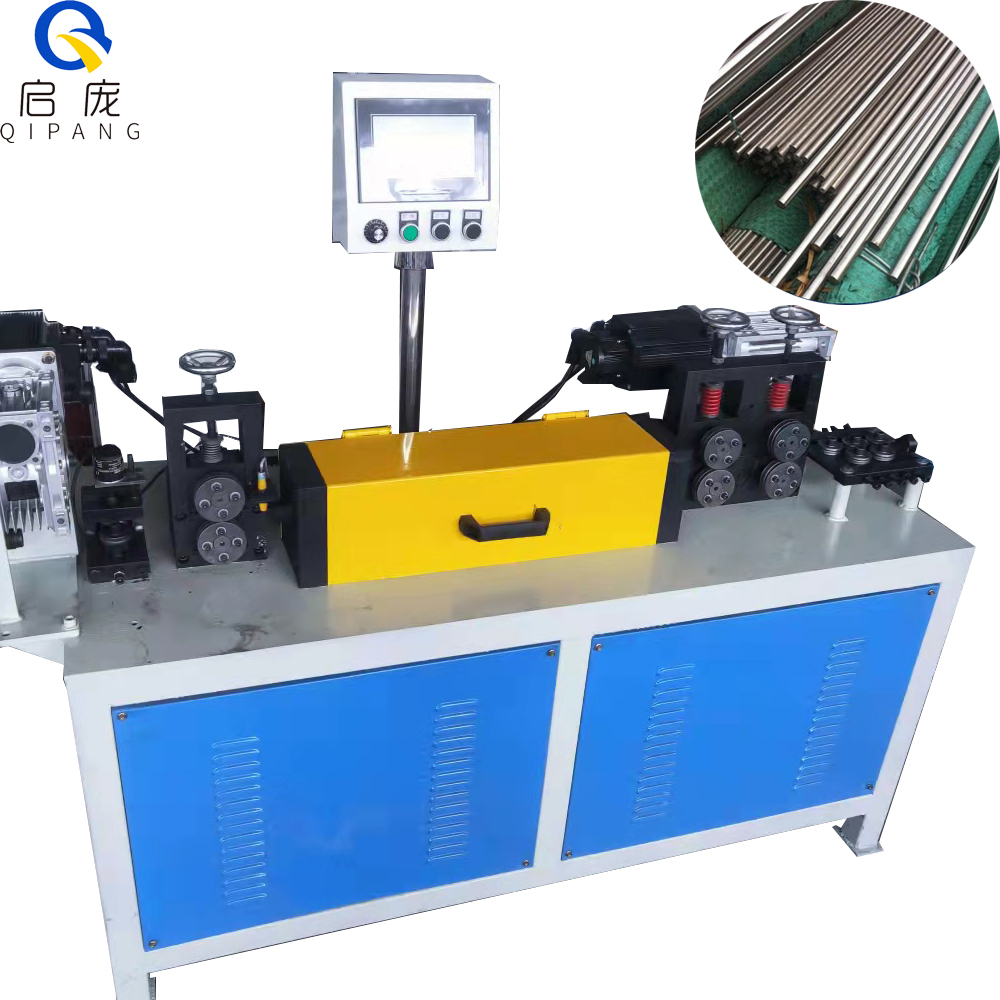

1-3 CNC Double Servo Straightening and Cutting Machine Machine size 1.6*0.6*1.4 meters (manual measurement) Motor power 1KW cut-off motor, 2kw feeding motor, 3kw ordinary motor drives the straightening drum

The straightening part generally uses alloy half molds (special material molds can be changed for no scratch effect) (the molds without scratch effect wear faster) PLC touch screen control system Whole machine weight 460kg 3-6 CNC Double Servo Straightening and Cutting Machine

Machine size 1.6*0.6*1.4 meters (manual measurement) Motor power 2KW cut-off motor, 2.6kw feeding motor, 3kw ordinary motor drives the straightening drum

The straightening part generally uses alloy half molds (special material molds can be changed for no scratch effect) (the molds without scratch effect wear faster) PLC touch screen control system Whole machine weight 460kg

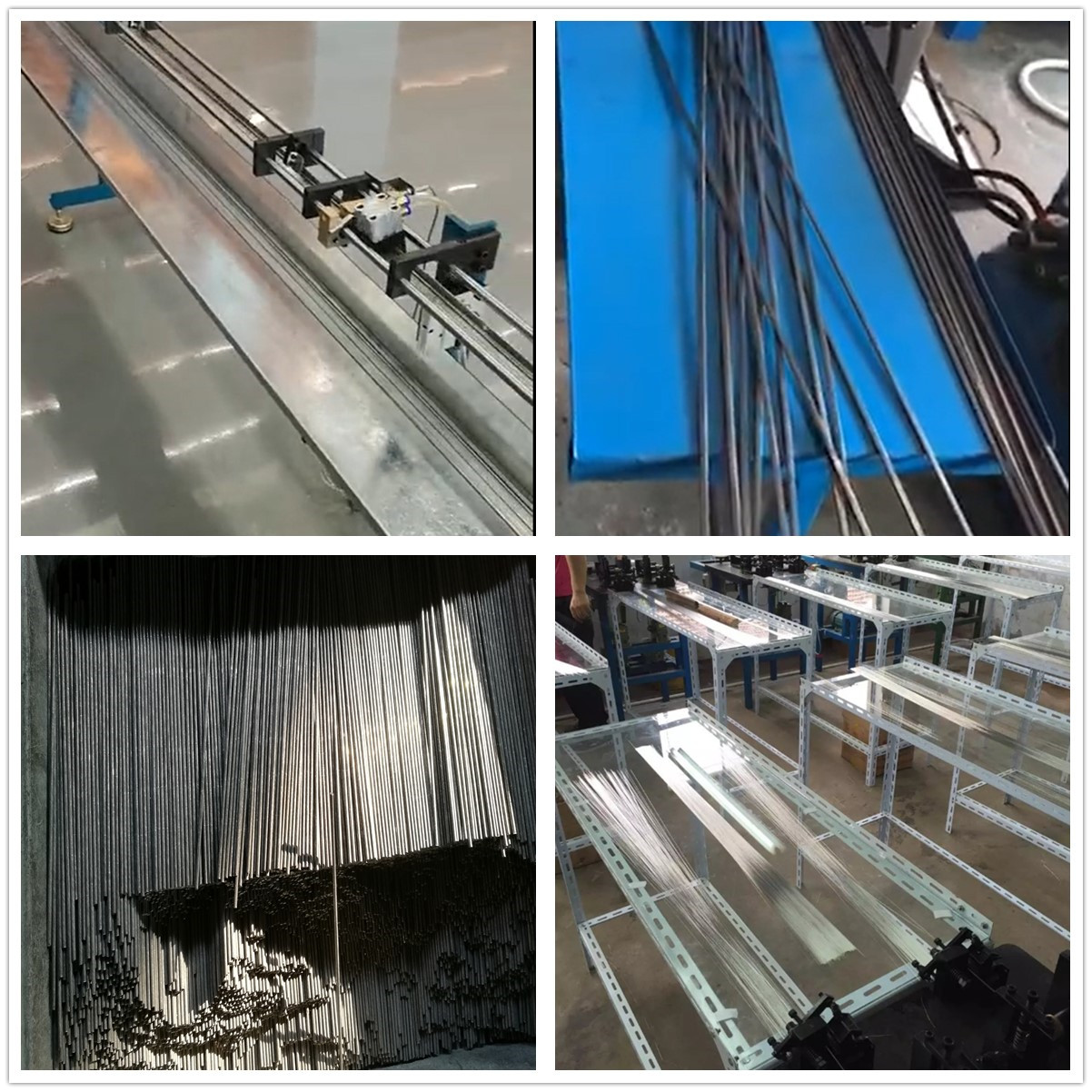

Straightening effect display

Straightener series

Customer Make QIPANG Wire Straightener

We can design and produce the wire straightener according to customer requirements.

1. Material ( steel,copper )

2. Diameter of steel wire or steel tube or copper tube

3. Operating speed ( m / min )

4. Single plane or double plane

5. If need qucik lever, if need guide roller, if need solid base

Equipment Reconstruction and Update

Just tell us the maker or brand of used wire straightener, and then we help you to select, optimize the suitable resulatiuons.

Before making an order, had better consult with us.

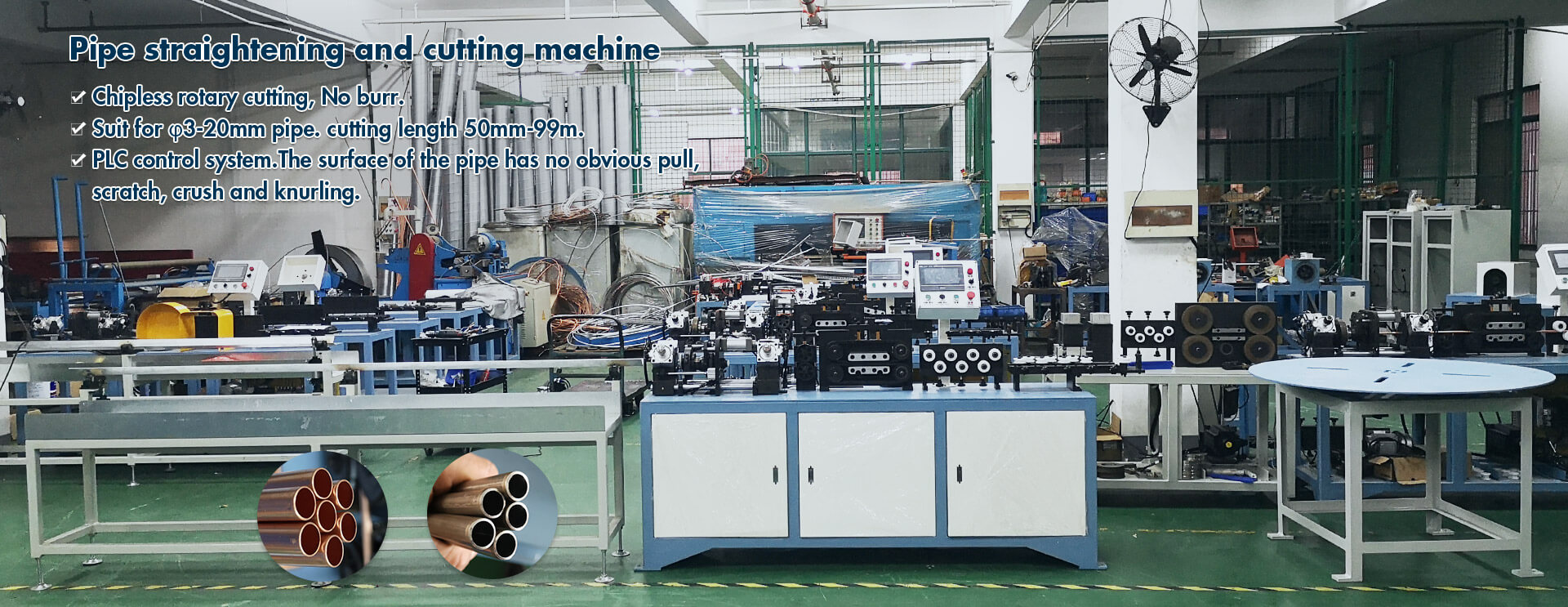

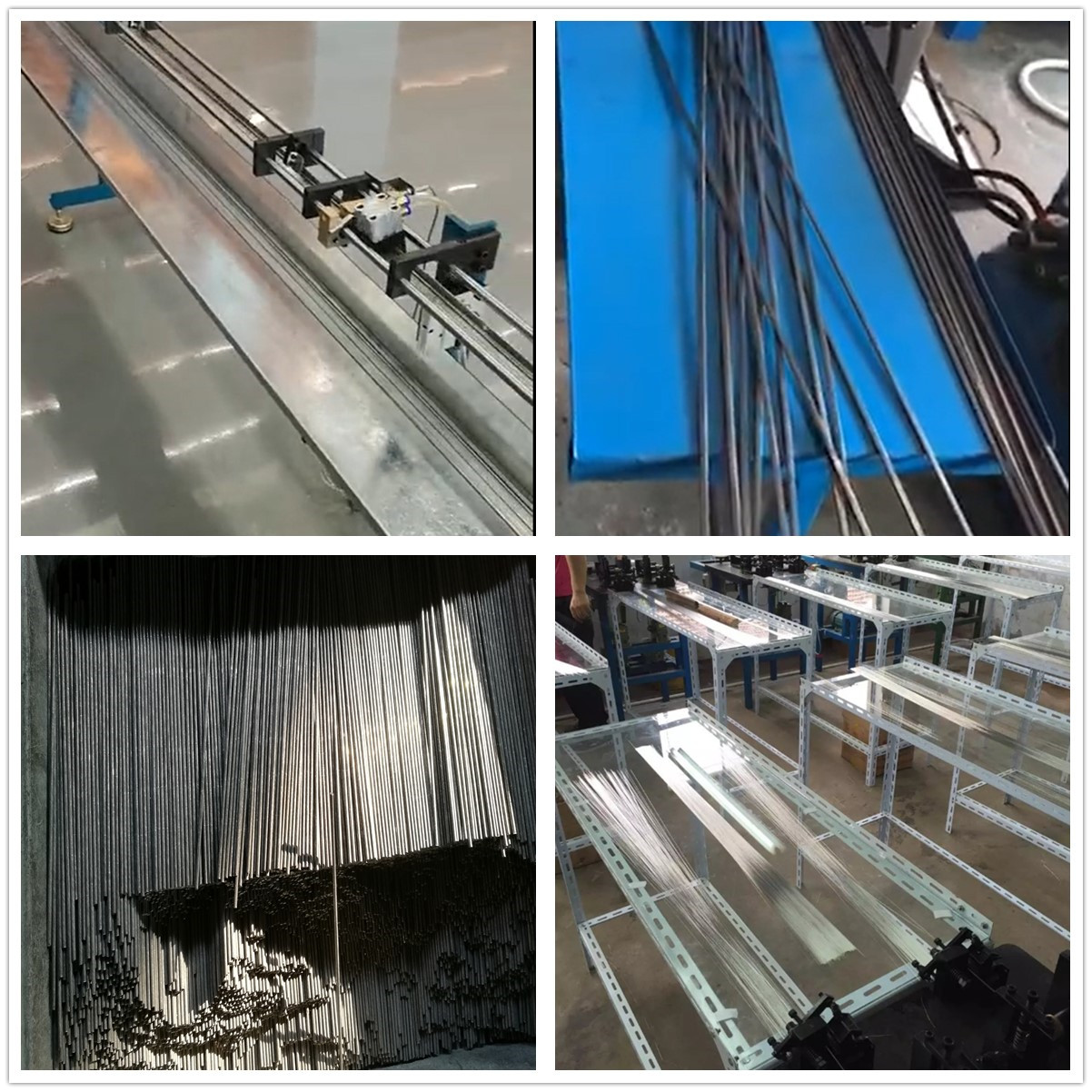

The picture of factory

Straightener Type

| 1-3 CNC Double Servo Straightening and Cutting Machine | ||||||||||

| Machine size | 1.6*0.6*1.4 meters (manual measurement) | |||||||||

| Motor power | 1KW cut-off motor, 2kw feeding motor, 3kw ordinary motor drives the straightening drum | |||||||||

| The straightening part generally uses alloy half molds (special material molds can be changed for no scratch effect) (the molds without scratch effect wear faster) | ||||||||||

| PLC touch screen control system | ||||||||||

| Whole machine weight | 460kg | |||||||||

| 3-6 CNC Double Servo Straightening and Cutting Machine | ||||||||||

| Machine size | 1.6*0.6*1.4 meters (manual measurement) | |||||||||

| Motor power | 2KW cut-off motor, 2.6kw feeding motor, 3kw ordinary motor drives the straightening drum | |||||||||

| The straightening part generally uses alloy half molds (special material molds can be changed for no scratch effect) (the molds without scratch effect wear faster) | ||||||||||

| PLC touch screen control system | ||||||||||

| Whole machine weight | 460kg | |||||||||

Straightening effect display

Straightener series

Customer Make QIPANG Wire Straightener

We can design and produce the wire straightener according to customer requirements.

1. Material ( steel,copper )

2. Diameter of steel wire or steel tube or copper tube

3. Operating speed ( m / min )

4. Single plane or double plane

5. If need qucik lever, if need guide roller, if need solid base

Equipment Reconstruction and Update

Just tell us the maker or brand of used wire straightener, and then we help you to select, optimize the suitable resulatiuons.

Before making an order, had better consult with us.

The picture of factory

About us

With more than 10 years of experience:

QIPANG has established an excellent reputation in the industry through the highest quality products designed and manufactured by outstanding engineering teams and providing our customers. After more than 10 years of continuous supply and maintenance of the highest quality machinery, tools, and accessories to the wire straightening industry, this excellent word of mouth continues today.

FAQ

We are a factory . We can promise you a short lead time and best price if you purchase our machine. We also have our own trading

department.

department.

Quality is the first priority. We have strict purchasing system to ensure the quality of spare parts. We have experienced workers

to assemble and test machine.

webcam, online chat (Google talk, Facebook, Skype). Please contact us once the machine has any problem. Best service will be

offered.

relative files for checking.

Q6 : Will you send the installed machine or machine parts?

We will install the machine and test the machine before delivery. And the machine can be used directly after receiving the machine

Please contact us once the machine has any problem. Best service will be

offered.